Essential Furnace Maintenance Tips: Expert Advice for Effective Furnace Care

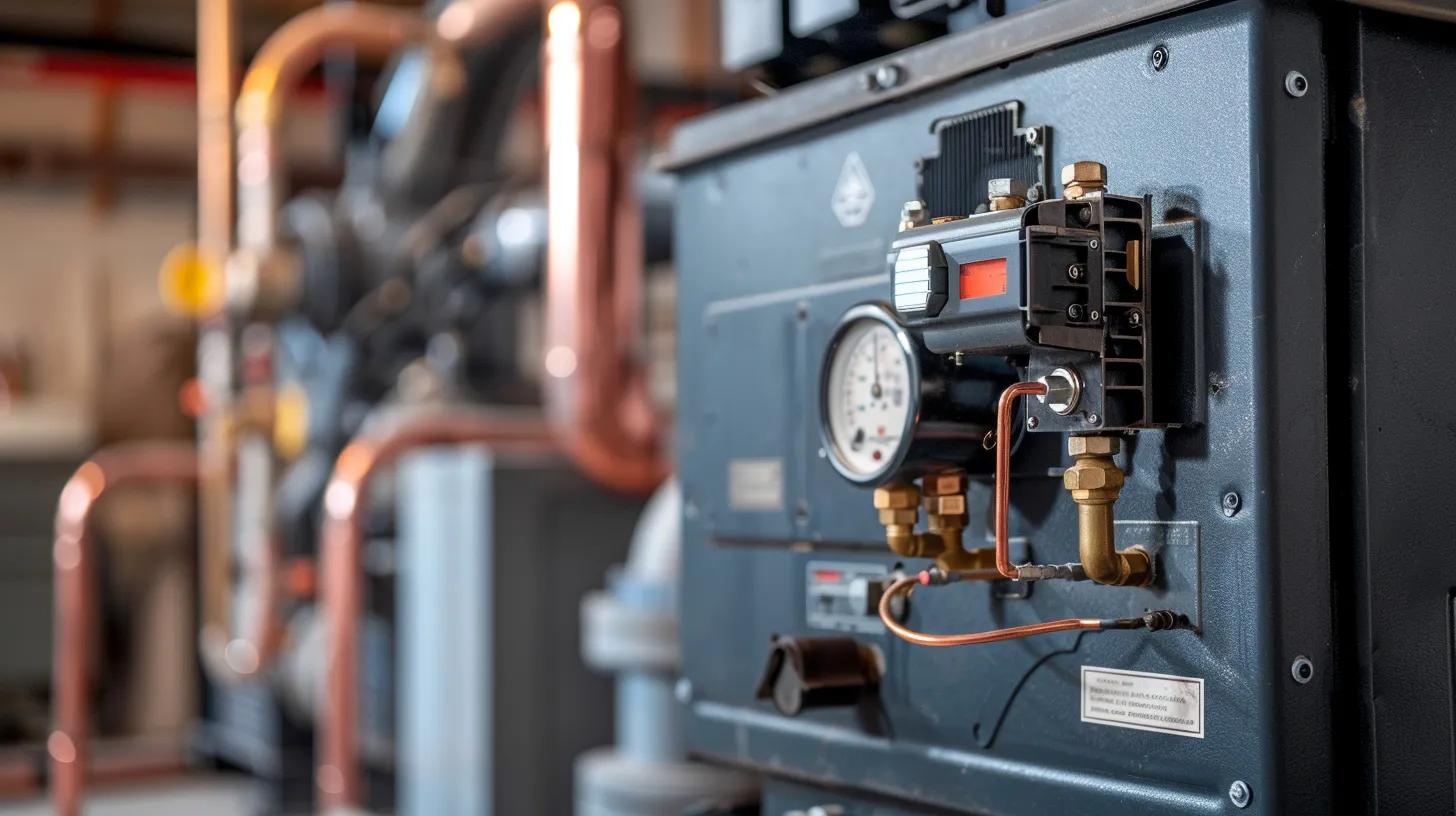

When winter temperatures drop, nothing matters more than a reliable furnace to keep your home comfortable and safe. Regular furnace maintenance tips not only enhance performance but also prevent unexpected breakdowns and reduce energy costs. This comprehensive guide covers the key steps for effective furnace care, offering professional insights into essential furnace servicing practices that protect your comfort and investment year after year.

Service Frequency & Warranty Compliance

Optimal furnace performance requires annual professional inspections (early fall) and monthly/seasonal homeowner checks. Proactive tune-ups prevent stress, reduce emergency repairs, and maintain warranty. Professionals inspect combustion safety, heat exchanger, gas lines, and clean burners, providing a report. Homeowners perform monthly filter checks, vent inspections, and CO detector tests, plus seasonal furnace area cleaning and thermostat checks. Documented annual professional servicing is often required for full warranty; keep all service records.

Comprehensive Furnace Maintenance Tips

A comprehensive furnace maintenance checklist covers filters, burners, flame sensors, blower motor, thermostat, ducts, and safety devices, prioritizing safety and efficiency. The workflow starts with safe shutdown, moving from intake to combustion components, then controls and safety systems.

- Power and Gas Safety Check: Turn off power, confirm gas valve status.

- Air Filter Inspection/Replacement: Check/replace filters for proper airflow.

- Visual Combustion Component Inspection: Inspect burners, flame sensor, and heat exchanger for damage.

- Blower and Motor Cleaning/Lubrication: Clean blower assembly and lubricate bearings

- Thermostat Calibration and Control Check: Verify accurate temperature control/schedules.

The table below summarizes recommended frequencies and tools for each maintenance item:

Component | Recommended Frequency | Tools / Supplies |

|---|---|---|

Air filter | Monthly to quarterly | Replacement filters, gloves |

Flame sensor | Annually or if ignition issues | Soft cloth, emery cloth, screwdriver |

Burners | Annually (cleaning) | Compressed air, soft brush, vacuum |

Blower motor | Annually, more if dusty | Vacuum, soft brush, light oil (if applicable) |

Thermostat | Annually (calibration) | Small screwdriver, multimeter |

Vents/registers | Seasonal | Vacuum, brush, damp cloth |

Carbon monoxide detector | Monthly tests, battery replace yearly | New batteries, detector test kit |

DIY Furnace Maintenance Tips & Safety

When to Call a Professional

Stop DIY work and call a licensed HVAC technician for suspected gas leaks, cracked heat exchangers, persistent ignition failures, complex electrical faults, or major disassembly. Safety-critical issues like yellow flames, CO alarms, or visible heat exchanger damage require immediate professional intervention. If basic troubleshooting fails, a technician has diagnostic tools with furnace maintenance tips. Prioritize safety and expertise.

| Brand | SEER2 Rating Range | Warranty Coverage | Key Strength |

|---|---|---|---|

| Lennox | 14–23 | 10-year limited | High-efficiency models |

| Carrier | 13–22 | 10-year parts | Quiet operation |

| Trane | 14–22 | 10-year limited | Robust durability |

| Rheem | 13–20 | 10-year parts | Value-oriented solutions |

| American Standard | 14–24 | 10-year limited | Precise comfort control |

Benefits of Regular Effective Furnace Care

Effective furnace care provide energy savings, reduced breakdown risk, extended lifespan, and improved indoor air quality/safety. Cleaner combustion, calibration, and unobstructed airflow reduce fuel consumption and emissions, while early wear detection prevents failures. These benefits mean lower utility bills, fewer emergency repairs, and a safer home.

Benefit Category | Metric / Attribute | Typical Estimated Value |

|---|---|---|

Energy efficiency | Reduced fuel/electric use | 5–30% savings range |

Repair frequency | Fewer emergency repairs | Noticeable decrease in service calls |

Lifespan extension | Additional operational years | 2–7 years typical extension |

Indoor air quality | Particle reduction via filters | Significant reduction depending on filter MERV |

Safety | Reduced CO and combustion risk | Lower likelihood of hazardous events |

Maintenance improves energy efficiency by restoring proper combustion, enhancing heat transfer, and preventing airflow restrictions. It mitigates wear mechanisms (motor overheating, bearing wear, corrosion), extending furnace service life. Regular servicing ensures filters/ducts remove particulates and complete combustion, enhancing indoor air quality and safety. Environmentally, it reduces fuel consumption and greenhouse gas emissions.

Troubleshooting Common Problems

Troubleshooting follows a symptom → cause → fix format, guiding safe homeowner interventions and identifying when to call a technician. This prioritizes simple checks (thermostat, power, filter), then ignition and airflow, before professional diagnosis. Common symptoms include no heat, strange noises, and a yellow pilot light.

No Heat: Often stems from thermostat issues, power interruptions, ignition failures, or airflow restrictions. Check thermostat settings/batteries, power switch/breaker, and replace dirty filters. If ignition fails, inspect igniter/pilot assembly and flame sensor. Persistent issues, gas problems, or gas odors require immediate essential furnace servicing.

Strange Noises: Squealing (blower belt/bearing wear), rattling (loose panels/debris), banging (delayed ignition). Tighten loose panels, clear blower debris. Squeal indicates bearing lubrication or belt replacement. Banging/loud combustion noises require immediate shutdown and professional evaluation.

Yellow Pilot Light: Yellow/orange pilot flame indicates incomplete combustion and carbon monoxide risks (proper flame is blue). Safely shut down, ventilate, and test CO detectors. Persistent yellow flames suggest burner blockage, improper air-fuel mixture, or a cracked heat exchanger—all needing professional inspection. Never operate with incomplete combustion signs.

Professional Services & Smart Technologies

Service Item | DIY Feasible? | Typical Cost Range | When to Call a Pro |

|---|---|---|---|

Filter change | Yes | $0–$50 (filter only) | N/A |

Flame sensor cleaning | Yes | Minimal (DIY) | If ignition issues persist |

Burner cleaning | Sometimes | $100–$300 (pro) | If soot/corrosion present |

Heat exchanger inspection | No | $150–$500+ | Always call pro for cracks |

Electrical/control board repair | No | $200–$800+ | Call a licensed technician |

Call a licensed HVAC technician immediately for gas leaks, CO alarm triggers, visible heat exchanger damage, major electrical faults, or unsafe combustion. Smart thermostats and modern furnace controls enhance maintenance with remote diagnostics, runtime data, and reminders, detecting inefficiencies earlier. They log error codes and operating patterns, helping technicians pinpoint faults. Advanced components often require specialized knowledge and calibration, emphasizing trained technicians.

Seasonal Furnace Preparation

How Maintenance Enhances Indoor Air Quality and Safety

Effective furnace care directly impacts the air your family breathes. Clean filters and ducts trap allergens and dust, while proper combustion minimizes harmful byproducts. Technicians also verify limit switches and safety devices during each inspection.

This combination of furnace maintenance tips and professional oversight ensures a healthier, safer home, especially important for families with children or elderly members.

Conclusion

Investing in regular furnace maintenance tips ensures lasting comfort, safety, and energy savings. Combining your own effective furnace care routines with annual professional tune-ups forms a complete maintenance strategy.

By prioritizing essential furnace servicing, you’ll extend your equipment’s life, lower utility costs, and create a healthier indoor environment, season after season. Trust in essential furnace servicing today to enjoy a warmer, safer home tomorrow.

Top 5 FAQs About Furnace Maintenance

1. How often should I replace my furnace filter?

Check monthly and replace every 1–3 months, depending on filter type and indoor air quality.

2. Can I perform furnace maintenance myself?

Yes, basic tasks like filter changes and vent cleaning are DIY-safe. Leave gas and electrical work to professionals.

3. What’s included in a professional furnace tune-up?

Inspection, cleaning, lubrication, combustion testing, and safety checks to ensure optimal operation.

4. How does maintenance affect energy efficiency?

Clean, tuned furnaces use less fuel and operate more efficiently, lowering utility costs.

5. What are the signs I need professional furnace repair?

Unusual noises, poor heating, yellow flames, frequent cycling, or gas odors indicate it’s time to call an expert.